Juntai Tube Settler Installation Guide: Precision Engineering for Optimal Clarifier Performance

Step-by-Step Tube Settler Installation Process

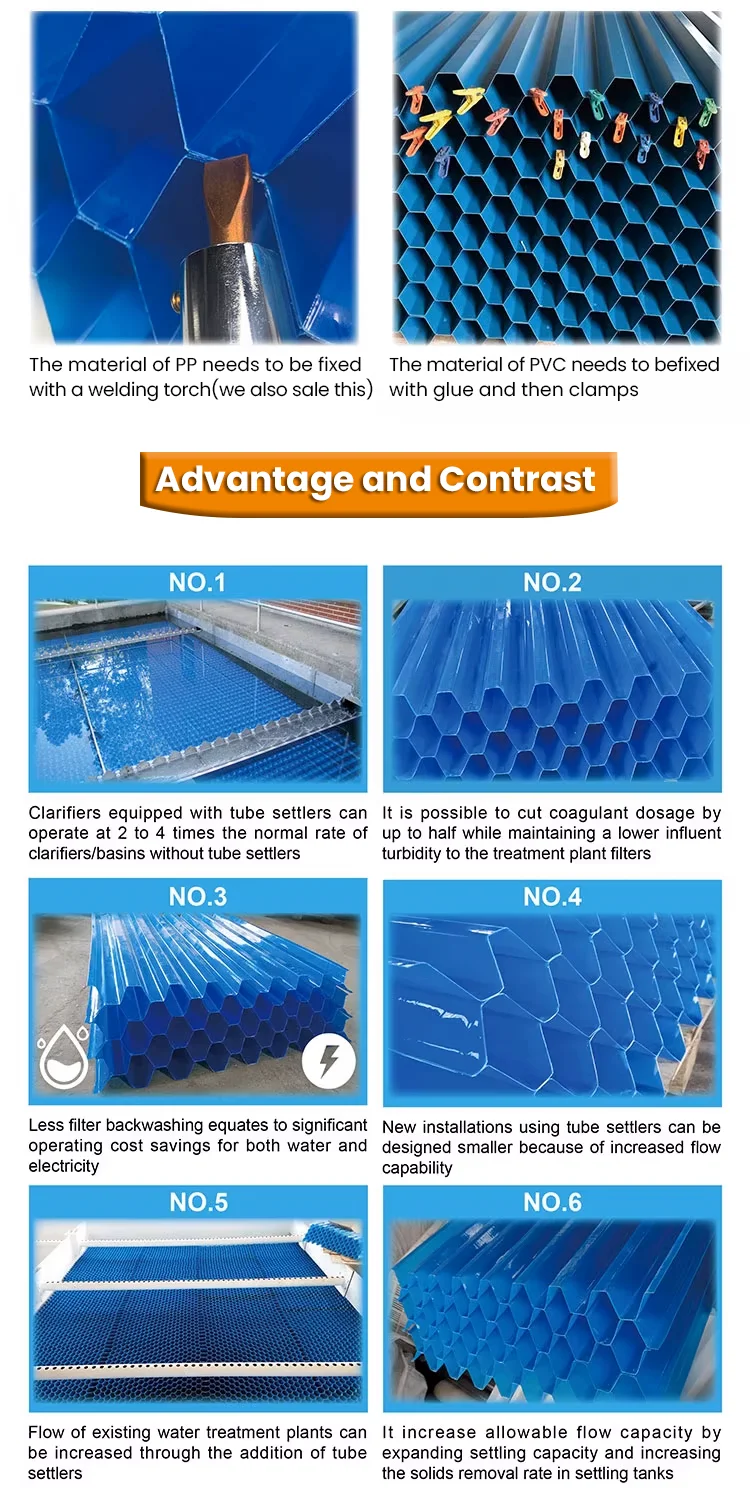

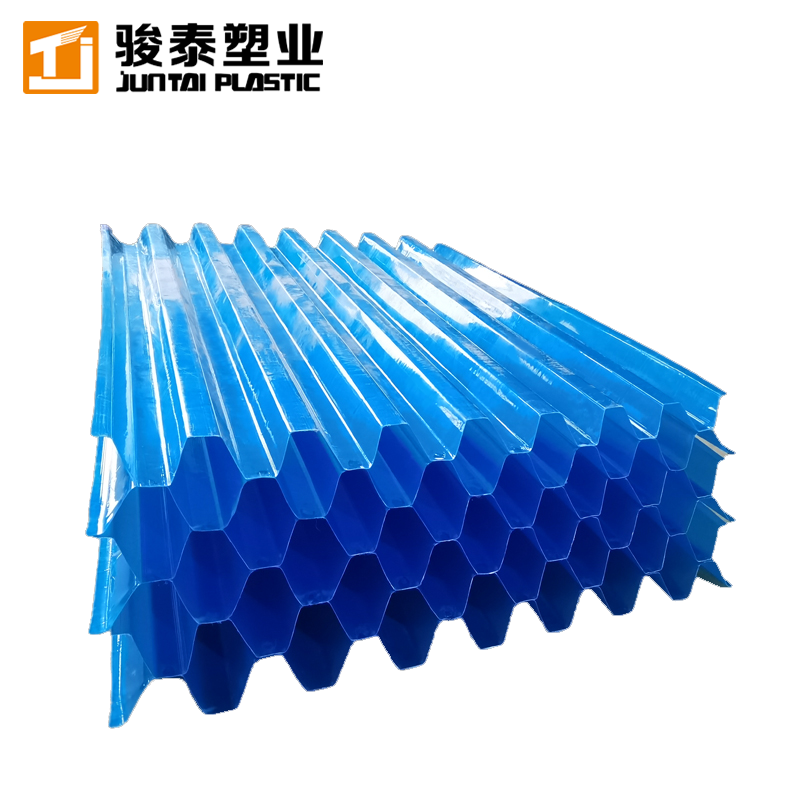

Juntai's inclined tube settler systems are designed for seamless integration into water treatment plants, STP tanks, and industrial clarifiers. Below is a detailed breakdown of the installation workflow to ensure maximum sedimentation efficiency and system longevity.

Phase 1: Pre-Installation Preparation

Tank Assessment

- Measure the tube settler tank dimensions (L x W x H) to calculate module quantities.

- Verify structural integrity of supports for lamella tube settler clarifier loads (≥150 kg/m²).

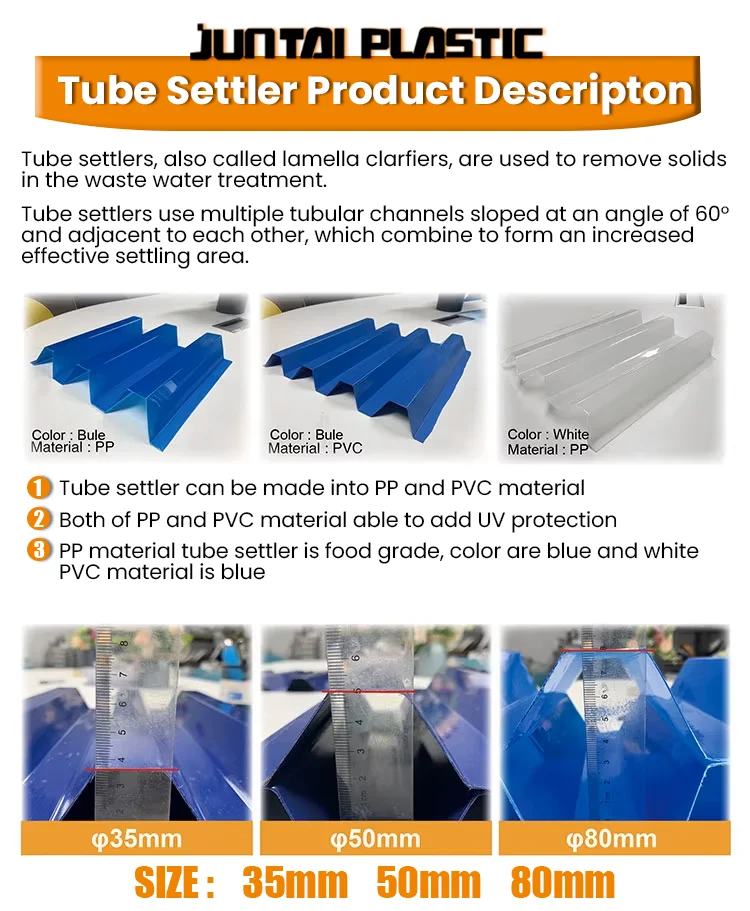

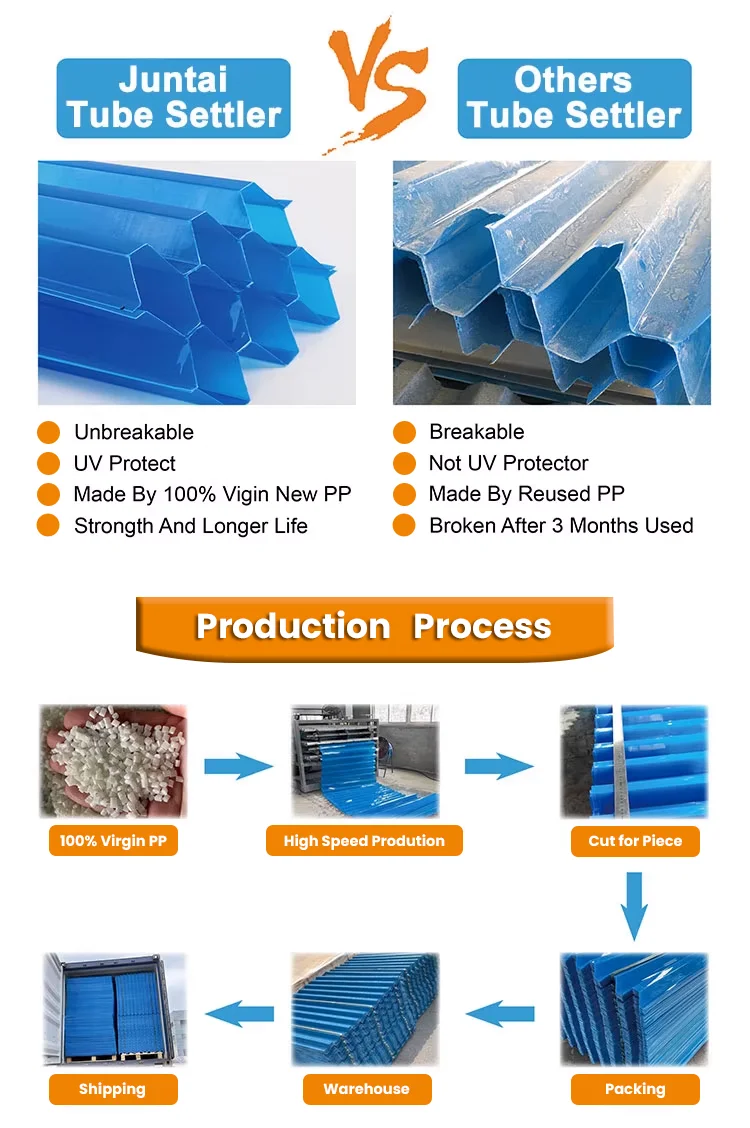

Material Selection

- Choose PP tube settler for corrosive environments (e.g., chemical wastewater) or PVC tube settler media for UV-exposed outdoor installations.

Tool Checklist

- Laser level, stainless steel brackets, epoxy anchors, and non-abrasive cleaning tools.

Critical Installation Parameters for Lamella Systems

| Parameter | Specification |

|---|---|

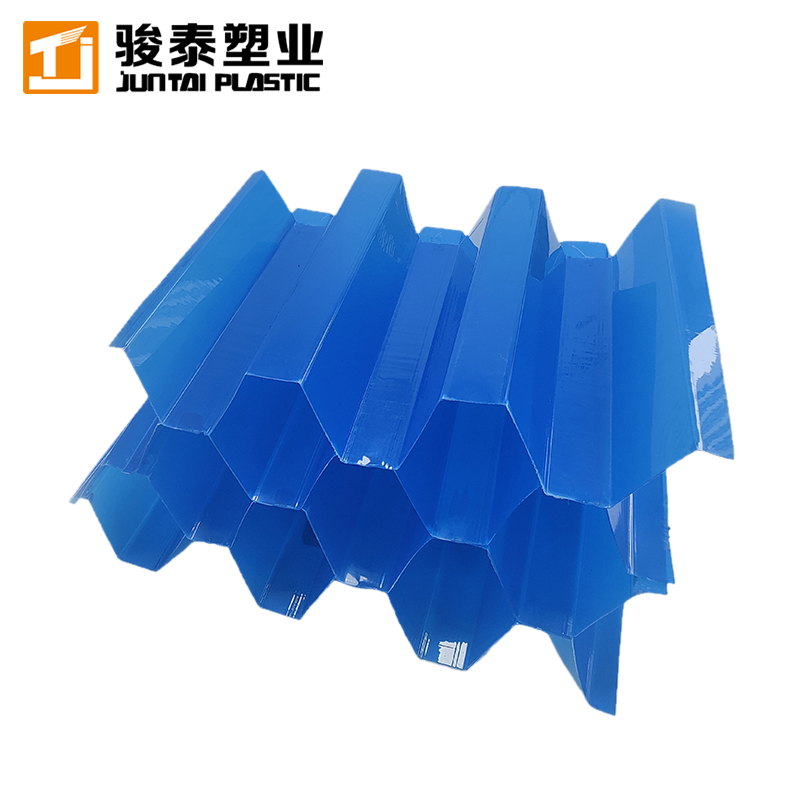

| Inclination Angle | 60° ±2° (optimizes sludge sliding velocity) |

| Module Spacing | 50-100 mm between lamella tube layers |

| Flow Distribution | ≤5% velocity variance across tube settler media |

| Anchoring Force | 25 N·m torque for PVC / 18 N·m for PP |

| Post-Installation Test | 24-hour dry run + turbidity calibration |

Phase 2: Installation Best Practices

Frame Assembly

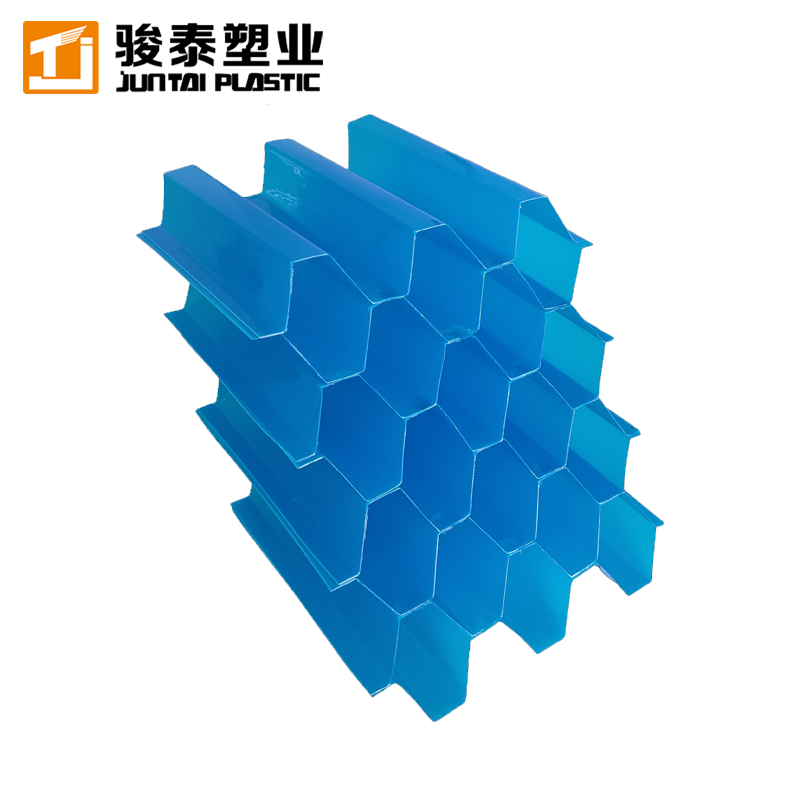

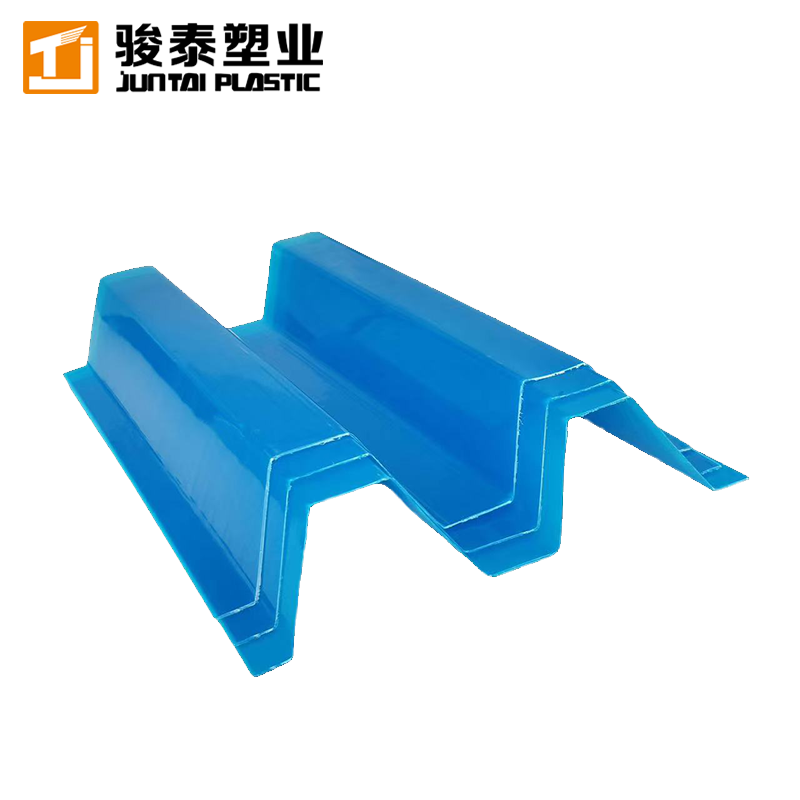

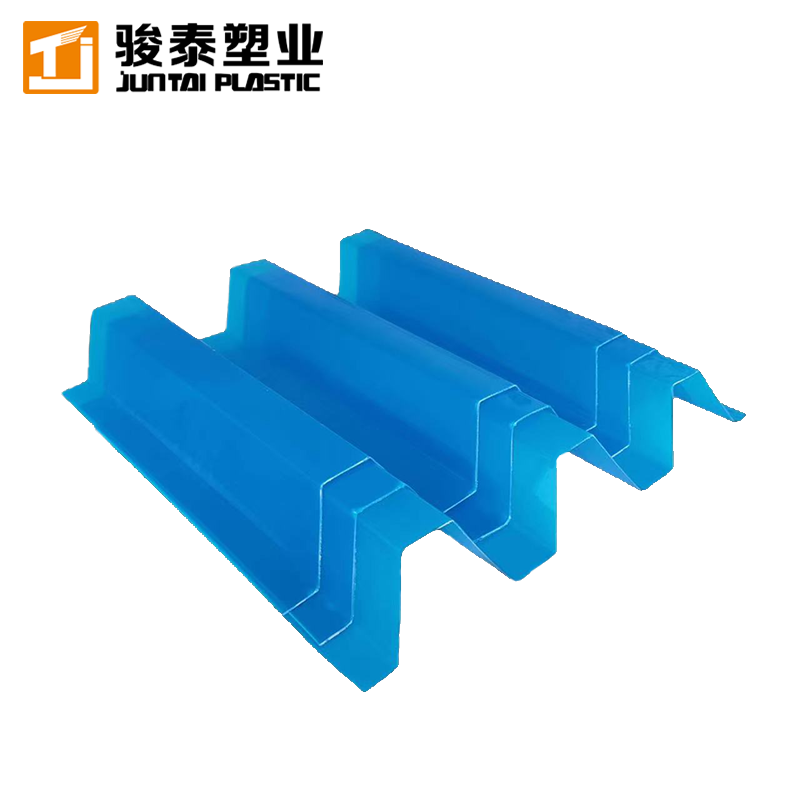

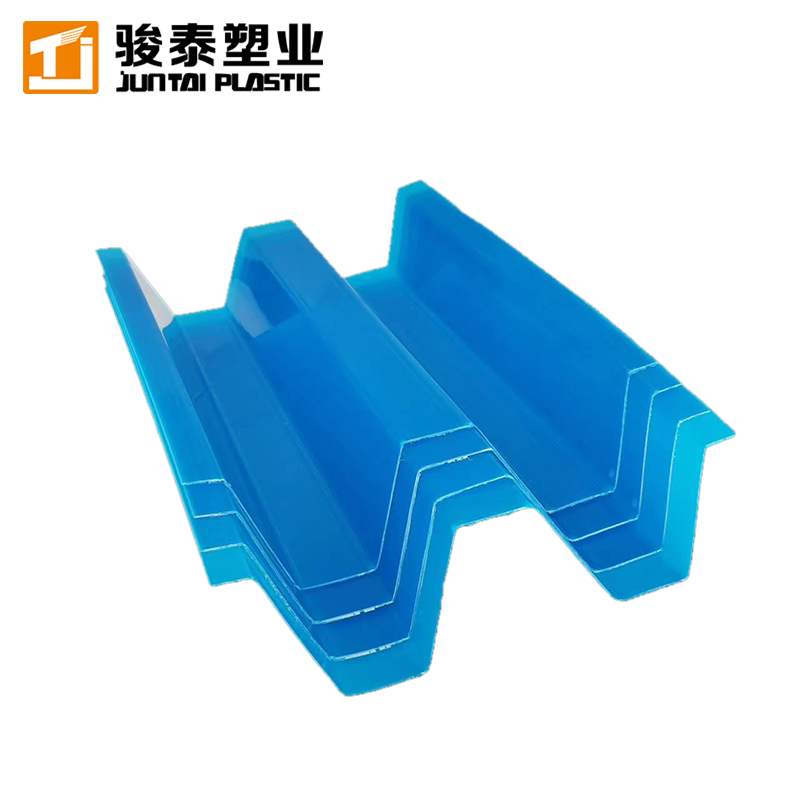

- Assemble stainless steel support grids using laser-leveled alignment. For plate and tube settlers, interlock PP/PVC modules with T-slot connectors.

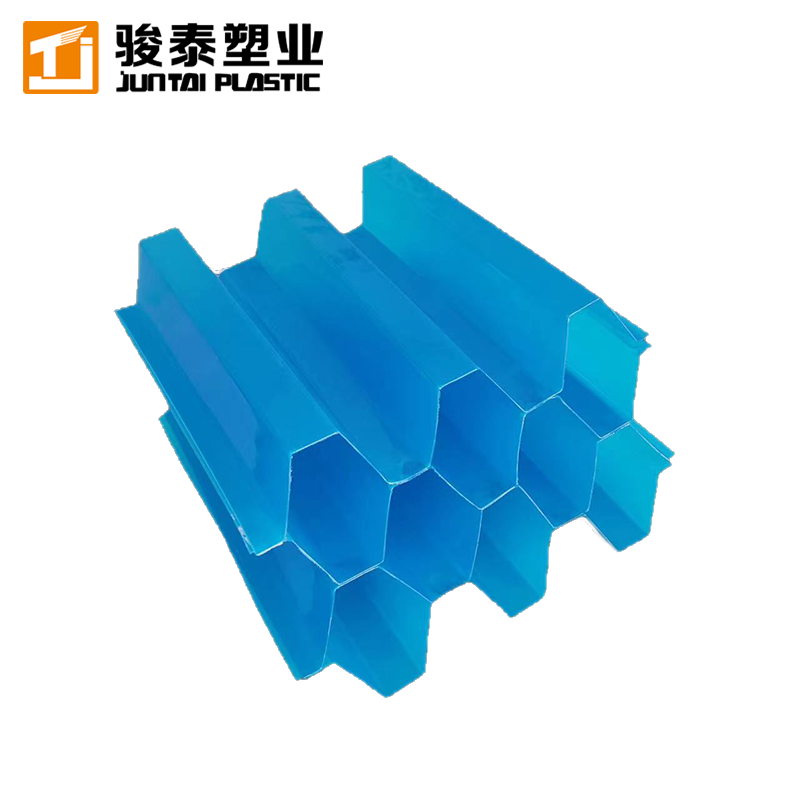

Module Placement

- Stack lamella tube settler modules at 60° angles, ensuring tongue-and-groove edges are fully engaged. Use silicone gaskets for waterproof sealing.

Anti-Clogging Measures

- Install pre-filters (80-100 µm) upstream to protect pvc tube settler media from debris.

UV Protection (Outdoor STPs)

- Apply Juntai's proprietary UV-resistant coating (0.2 mm thickness) to tube settler in water treatment plant exposed to sunlight.

PP vs. PVC Installation Nuances

| Factor | PP Tube Settler | PVC Tube Settler Media |

|---|---|---|

| Thermal Expansion | 1.5 mm/m (require 5mm expansion gaps) | 0.8 mm/m (3mm gaps sufficient) |

| Chemical Bonding | Acrylic adhesives prohibited | Solvent welding recommended |

| Maintenance Access | Monthly inspection for biofilm | Quarterly cleaning (alkaline wash) |

Post-Installation Optimization

Flow Calibration

- Adjust inlet weirs to maintain 0.8-1.2 m³/h·m² surface loading rate for tube settlers water treatment efficiency.

Sludge Management

- Install automated scrapers for lamella plate settler hybrid systems to prevent sludge bridging.

Performance Monitoring

- Use IoT sensors to track turbidity (<5 NTU) and pressure drop (<0.15 bar) in real time.